HWG – HYDRAULIC WHEEL GRIPPERS

Wheel Grippers are ground-mounted, static holding systems critical in the unloading process of coal train railcars, using rotary railcar dumpers. Wheel Grippers hold railcars while the positioner is returning to position the next railcar and secure railcars throughout the rotation of the car dumper. Wheel grippers grip / clamp the wheels of railcars and hold it tightly in place during the unloading process.

BENEFITS

Unique mechanism extends gripping height on railcars wheels. This feature produces greater holding capacity with lower railcars wheel applied forces. The same mechanism allows for gripper bars to retract to the rail top level for less chance of impact damage from railcars and locomotives. Brelx rugged, short stroke hydraulic cylinders are mounted at the top of the wheel gripper and are easy to access and remove in place.

KEY FEATURES

- Rugged, short stroke hydraulic cylinders/actuators apply forces to the wheel, with 1 to 1 applied force ratio (does not use mechanical advantage)

- This means that no adjustment is ever required to compensate for gripper bar wear

- This adjustment has been a big source of problems with some wheel gripper designs

- Dual hydraulic cylinders for independent action of both gripper bars

- This allows for railcar wheel position horizontal float

- Gripper bars are retracted to solid stops below the top of a rail, helping to prevent damaging impacts with railcar wheels

- Wheel Gripper with a hydraulic actuator is designed to sustain a large number of cycles

- The rod, seals, piston, and jaw inserts are subject to minimum wear and tear

- Wheel gripper’s modular design for ease of inspection

- Wheel gripper hydraulic cylinders are easily accessed for removal or replacement

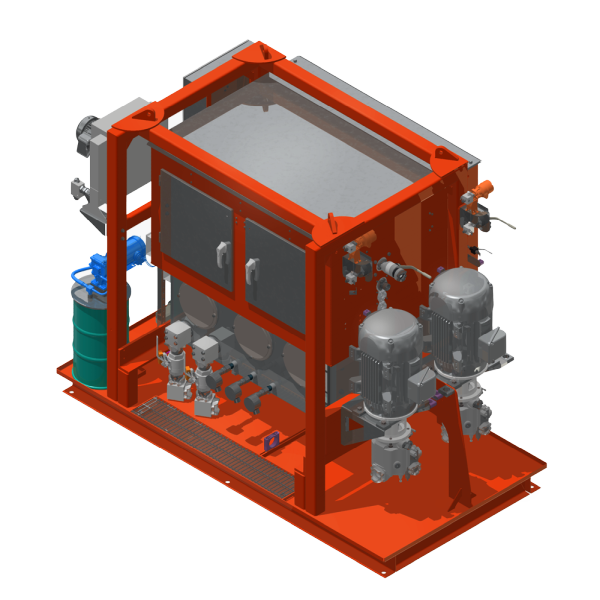

- Hydraulic Power Unit HPU customizable to meet the end users’ requirements

Electric linear actuator: R&D