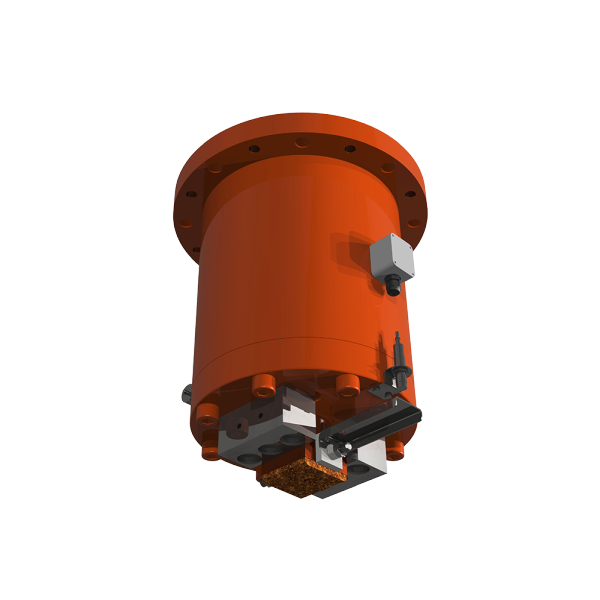

STATIC RAIL BRAKE – CLASSIC

Rail Brakes directly apply disc spring force on the top of the rail head. They utilize the weight of a crane in the braking process and provide the braking force along the rail. Once released, the brake hangs above the rail at a pre-designed clearance. Actual braking capacity depends on the applied force calculated with 0.5 coefficient of friction for static braking with serrated shoe.

STATIC RAIL BRAKE – SELF ADJUSTING

Self Adjusting Rail Brakes are designed with a two-stage braking process; first stage compensates shoe to rail head travel and the second stage provides full spring force on the top of a rail. Once released, the brake hangs above the rail at a pre-designed clearance. Actual braking capacity depends on the applied force calculated with 0.5 coefficient of friction for static braking with serrated shoe.

DYNAMIC RAIL BRAKE – CLASSIC

Rail Brakes directly apply disc spring force on the top of the rail head. They utilize the weight of a crane in the braking process and provide the braking force along the rail. Once released, the brake hangs above the rail at a pre-designed clearance. Actual braking capacity depends on the applied force calculated with 0.4 coefficient of friction for dynamic braking with a smooth friction shoe.

Rail brakes utilize the weight of a crane in the braking process and provide the braking force along the rail.

They are spring set and hydraulically released. Once released, the brake hangs above the rail at a pre-designed clearance. Actual braking capacity depends on the applied force and applicable coefficient of friction (different for static and dynamic braking).

Self Adjusting Rail Brakes were developed specifically to address problems with crane rail vertical fluctuations. Rail height fluctuations are typically caused over time by settling and fatigue failures of the rail support foundations. Rail height fluctuation has been a big problem for traditional rail brakes. It has either caused the rail brake to impact the rail brake (high rail), causing damage to the rail brake, crane and rail; or it has resulted in such large gaps between the rail brake and the rail (low rail) that the brake no longer produces adequate force or capacity.