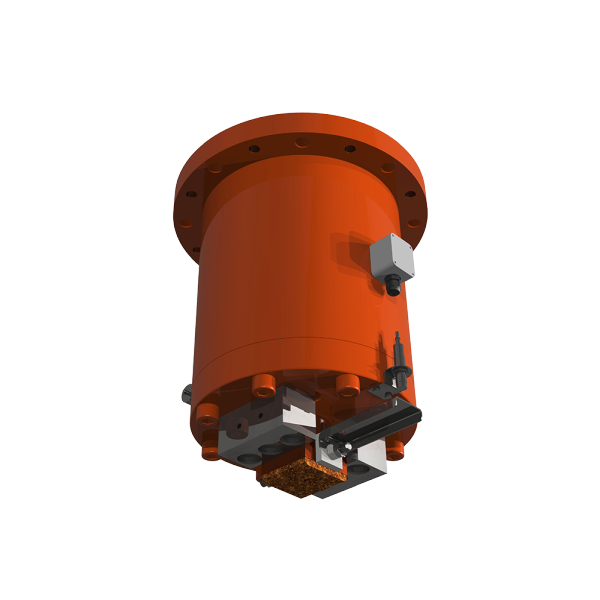

STATIC RAIL BRAKE – SELF ADJUSTING

Self Adjusting Rail Brakes are designed with a two-stage braking process; first stage compensates shoe to rail head travel and the second stage provides full spring force on the top of a rail. Once released, the brake hangs above the rail at a pre-designed clearance. Actual braking capacity depends on the applied force calculated with 0.5 coefficient of friction for static braking with serrated shoe.

BENEFITS

Brelx patented design with two stage breaking allows up to 38mm rail deviation while providing uniform rated capacity over the full range of movement. Provides consistently greater braking / holding force at increased shoe to rail clearances. It is a completely spring-set rail brake.

KEY FEATURES

Rail Brake Mechanism: Spring set – Hydraulic or Electric release

- Largest installation clearance (@ 38mm air gap) in the industry

- 100% spring-set type rail brake

- Flow control valve installed on the brake for controlled setting time

- IFM Proximity switch for release indication

- Serrated shoe easily removed and replaced

- Brakes are fabricated from high quality structural steel

- Compact design with low height allows retrofitting with adapter flanges

- Manual release (hand pump installed on the Hydraulic Power Unit)

Electric linear actuator: Installed inside rail clamp (integral unit)

- No hydraulic oil, no possibility for oil spill / leaks

- Means for mechanical release in case of power loss

- Prewired Junction box

- Mechanically adjustable control of setting time at site

- Electric actuators are cleaner, easier to control, and require less maintenance than hydraulic cylinders

- Electric actuators are much more reliable than hydraulic equipment

- Eliminate fossil-based hydraulic fluids which are potentially toxic to humans, along with being harmful to the environment

RELATED PRODUCTS

STATIC RAIL BRAKE – CLASSIC

Rail Clamps are static Storm Brakes which clamp onto both sides of a crane rail head, this provides the friction force necessary to prevent the crane from moving along it’s rails in case of sudden wind bursts. They are activated on loss of electrical power and are spring set. Can be hydraulically OR electrically released.

DYNAMIC RAIL BRAKE – CLASSIC

Thruster Service Brakes are mainly used on high speed driveshafts. They apply on the shaft disc to stop rotational motion. They are spring set and hydraulically OR electrically released.