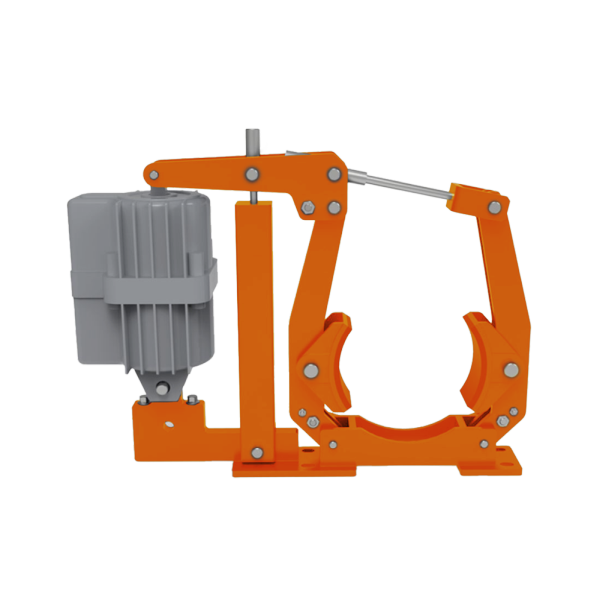

THRUSTER DRUM BRAKES – SDB DIN 15435

TSB braking force is applied to the brake shoes by a pre-stressed coil spring. The oversized brake shoes with friction material press on both sides of a rotating steel drum, providing the friction forces and thus braking capacity. Brake shoes are released from the disc by an electro-hydraulic thruster.

BENEFITS

Designed as service brakes to be applied on high speed shafts of modern drives, winches and hoists in order to slow or stop its rotational movement. Thruster disc brakes possess a scalable torque tube which means that torque can be adjusted to the exact torque amount which yields more precise braking and enhanced safety.

KEY FEATURES

Thruster Drum Brake Mechanism: Spring set – Hydraulic or Electric release

- Designed in accordance with DIN 15435 standard

- Enclosed spring tube increases protection against dirt and damage

- Stainless steel pins and self-lubricating bushings on all pivot points

- Brake shoes with friction material linings are easily removed and replaced

- Adjustable brake torque for more precise braking

- Equipped with Automatic Wear Compensator

- Brake shoe auto aligning device

RELATED PRODUCTS

THRUSTER DRUM BRAKES – SAB AISA US

The hydraulic wheel brake is crucial for controlling movement and ensuring safety during operation. It provides the necessary stopping power to manage the crane’s heavy loads, preventing unintentional rolling or drifting. These brakes use hydraulic pressure to apply force to the crane’s wheels, offering precise and controlled braking, especially on inclines or when the crane is stationary with a load.