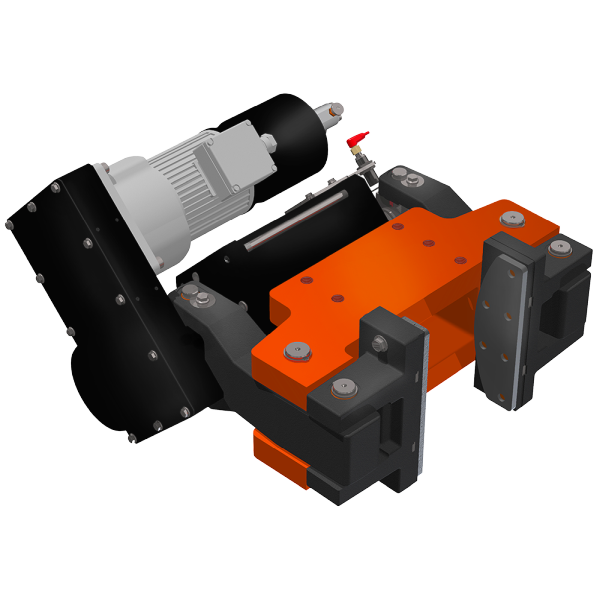

ELECTRIC WHEEL BRAKE – EWB

Wheel Brakes apply force generated by springs on both sides of crane wheels. Oversized brake shoes with friction material apply on the side flanges of idler wheels, providing the friction forces, and thus, braking capacity.

BENEFITS

Designed as parking brakes to be applied when equipment comes to a full stop, WB wheel brakes can be also used as dynamic brakes in an emergency (e-stop). By applying spring force directly on the wheel flanges, they minimize the amount of stress and strain otherwise placed on sill beams and truck assemblies of a crane.

KEY FEATURES

Wheel Brake Mechanism: Spring set – Hydraulic release

- Flow control valve installed on the brake for the controlled setting time 3 to 30 seconds

- Self-lubricating bushings and stainless steel pins on all pivot points

- Proximity switch for a released indication signal

- Brake shoes easily removed and replaced

- Made with high quality structural steel

- Nominal retracted clearance 1mm per side. Recommended maximum clearance 2mm per side

- Equipped with shoe alignment device

Operated and released by Brelx Hydraulic Power Unit HPU

Electric linear actuator: Installed inside rail brake (integral unit)

- No hydraulic oil removes the possibility for oil spills / leaks

- Means for mechanical release in case of power loss

- Prewired Junction box

- Mechanically adjustable control of setting time at site

- Electric actuators are cleaner, easier to control, and require less maintenance than hydraulic cylinders

- Electric Actuators are much more reliable than hydraulic equipment

- Eliminate fossil-based hydraulic fluids which are potentially toxic to humans, along with being harmful to the environment