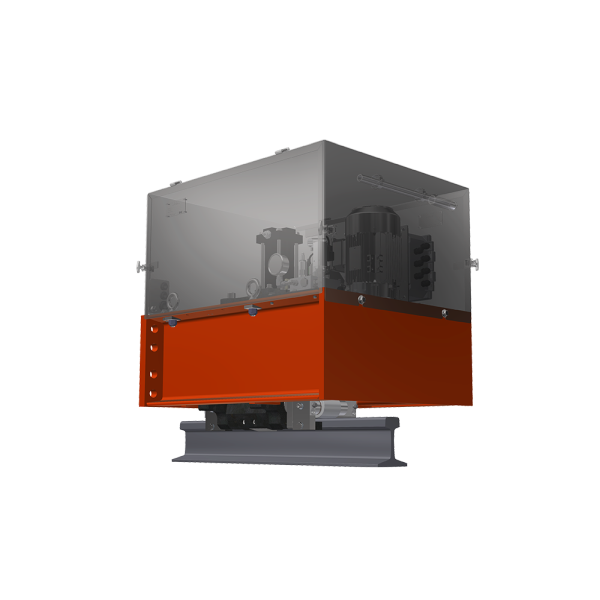

GUIDED RAIL CLAMP

Rail Clamps ride the rail on two hardened, low friction, Flangeless Cylindrical Rollers. Hardened Guide Blocks guide rail clamp along the rail. Capable to accommodate rails with large vertical fluctuations.

BENEFITS

A flangeless roller design eliminates expensive replacement of profiled guide wheels with worn-out flanges. The Rail Clamp’s jaws pull back behind the guide blocks protecting the serrated shoes from hitting the sides of the rail. This leads to minimal wear and tear. Guide Blocks are easily removable for quick maintenance and replacement. Mechanism compensates for the spring force loss, providing a constant designed clamping/holding capacity. Top suspended mechanism allows for very low mechanism float forces, removing the need for lubrification points.

AVAILABLE HOLDING CAPACITIES

- GRC-HS-SF from 50 kN to 1000 kN (SF Side Flange mounting)

- GRC-HS-TF from 50 kN to 700 kN (TF Top Flange mounting)

KEY FEATURES

Rail Clamp Mechanism: Spring set – Hydraulic or Electric release

- Rail Clamp shoes and mechanism retract completely above the rail head

- Mechanism weight is evenly distributed on four low friction bearings guided on a channel bar at the top of the rail clamp

- Low friction mechanism stability device allows for the reliable positioning on the rail and setting of the rail clamp mechanism

- Top suspended mechanism allows for very low mechanism float forces

- Top suspended mechanism

- Serrated shoes protected from hitting the rail sides

- Release of the serrated shoes and mechanism retraction done with a single, top-mounted hydraulic cylinder with no rod connection.

- Mechanism compensates force loss, providing a constant designed clamping/holding force

- Caging bolts for mechanical release and maintenance safety

- Horizontal Float: ± 30mm

- Vertical Float: ± 25 mm

- Mechanism caging bolts in released position for maintenance safety

- Rail clamp mounted on the crane via a Side Flange

- Marine grade C4 paint system for superior corrosion protection

- Stainless steel removable cover with the inspection doors located on both sides of a rail clamp (Side Flange mount model)

Hydraulic Power Unit: Internal

- Motor / Pump controlled by a pressure switch

- Adjustable setting time (8 – 30 sec)

- Hand Pump for hydraulic release

- Prewired Junction box.

- Solenoid valve with manual override

- Solenoid coil with LED indicator

- Integrated Temperature/Level Switch

Electric linear actuator: Installed inside rail clamp (integral unit)

- No hydraulic oil, no possibility for oil spill / leaks

- Means for mechanical release in case of power loss

- Prewired Junction box

- Mechanically adjustable control of setting time at site

- Electric actuators are cleaner, easier to control, and require less maintenance than hydraulic cylinders

- Electric actuators are much more reliable than hydraulic equipment

- Eliminates fossil-based hydraulic fluids which are potentially toxic to humans, along with being harmful to the environment